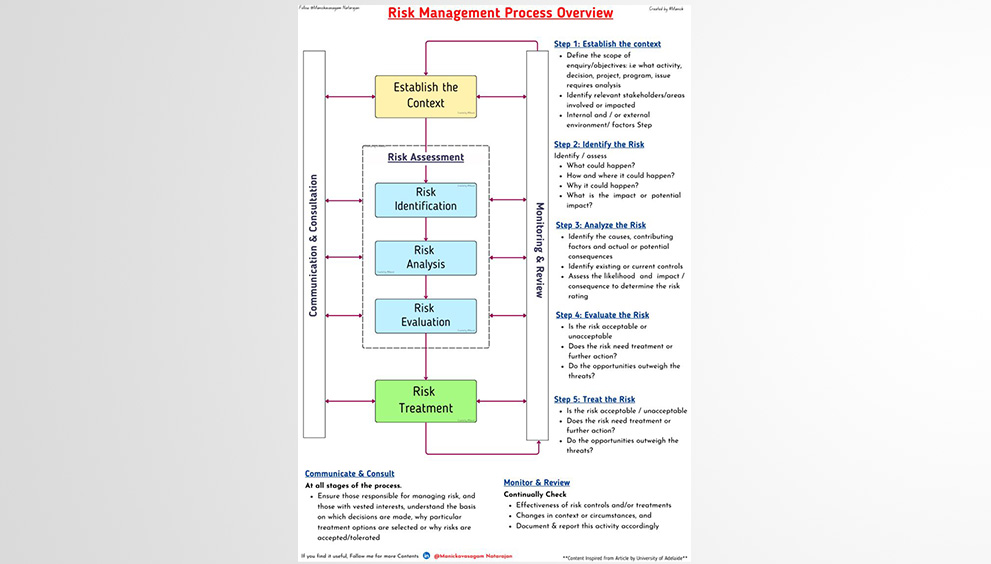

𝗦𝘁𝗲𝗽 𝟭: 𝗘𝘀𝘁𝗮𝗯𝗹𝗶𝘀𝗵 𝘁𝗵𝗲 𝗰𝗼𝗻𝘁𝗲𝘅𝘁

–> Define the scope of inquiry/objectives: i.e what activity, decision, project, program, or issue requires analysis

–> Identify relevant stakeholders/areas involved or impacted

Internal and/or external environment/ factors Step

𝗦𝘁𝗲𝗽 𝟮: 𝗜𝗱𝗲𝗻𝘁𝗶𝗳𝘆 𝘁𝗵𝗲 𝗥𝗶𝘀𝗸

Identify/assess

–> What could happen?

–> How and where it could happen?

–> Why it could happen?

–> What is the impact or potential impact?

𝗦𝘁𝗲𝗽 𝟯: 𝗔𝗻𝗮𝗹𝘆𝘇𝗲 𝘁𝗵𝗲 𝗥𝗶𝘀𝗸

–> Identify the causes, contributing factors, and actual or potential consequences

–> Identify existing or current controls

–> Assess the likelihood and impact/consequence to determine the risk rating

𝗦𝘁𝗲𝗽 𝟰: 𝗘𝘃𝗮𝗹𝘂𝗮𝘁𝗲 𝘁𝗵𝗲 𝗥𝗶𝘀𝗸

–> Is the risk acceptable or unacceptable

–> Does the risk need treatment or further action?

–> Do the opportunities outweigh the threats?

𝗦𝘁𝗲𝗽 𝟱: 𝗧𝗿𝗲𝗮𝘁 𝘁𝗵𝗲 𝗥𝗶𝘀𝗸

–> If existing controls are inadequate identify further treatment options

–> Devise a treatment plan

–> Seek endorsement & support for treatment

–> Determine the residual risk rating once the risk is treated

——————————————————–

If you find it useful, please 👍🏻👏🏻❤️💡🔁

Follow Manickavasagam Natarajan for more exciting posts on Quality, Lean Manufacturing, Operational Excellence, Leadership, and Inspiration🔔🔔🔔

hashtag#qaqc hashtag#lean hashtag#leansixsigma hashtag#operationalexcellence hashtag#manufacturing

hashtag#iso hashtag#mechanicalengineering hashtag#production hashtag#leadership

hashtag#quality hashtag#safety hashtag#oilandgas hashtag#iso9001 hashtag#audit hashtag#scm hashtag#purchase

![Remaining silent during an investigation is a fundamental right: Telangana HC [Read Judgment]](https://surakshitbharatabhiyan.org/wp-content/uploads/2024/04/lj_3728_c8f7ecd3-a0e9-44f7-85aa-f77b9dae3a49.webp)